Nozzle Recognition System. 25 Nov 2018

Review 21 Nov 2019

This is device that fits on the Fuel Pumps Nozzle that has an accelerometer, gyro, compass , ultra low power wifi, Rfid Reader, Battery and battery monitoring

Here we are using the CC1310 instead of wifi and depending on the new GPS device that I will receiving today, we may not need the RFID Reader on the Nozzle. This would help in saving battery power.

To explain its function, let’s go step by step how the functionality is seen.

- The vehicle arrives to be filled at a Filling Station. The Fuel Cap is either at the left, right or more rarely at the back of the vehicle.

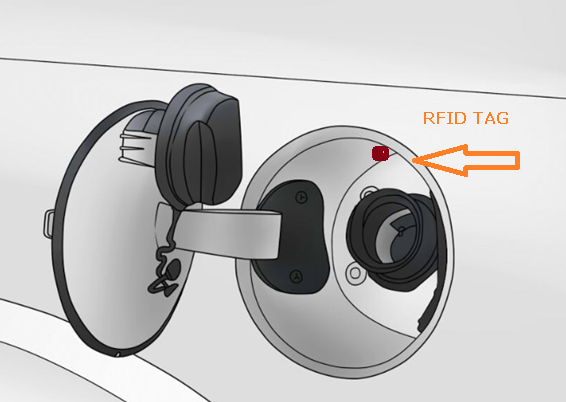

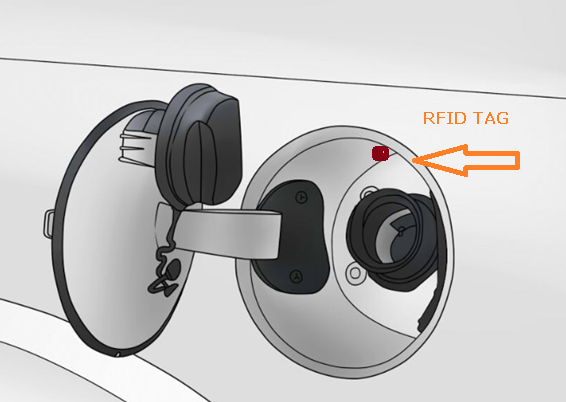

- Once the nozzle is put to the Tank, it will be in close proximity to an RFID Tag fitted to the vehicle. Alternatively, the Tag can be a keyfob tag that is fitted to the vehicle’s keys and this can be Tagged on an RFID Tag Reader on the Pump. The KeyFob authorization can be a standby solution to the GPS option should there be a problem locating the vehicle. The Vehicle will report via MQTT to the Web and the idea is that there will be Geo–ring fences for each fuelling bay. The Site, at that point would ideally be controlled by a Master Controller managing the Pumps or we may have a MQTT link to the Server on the PC that will inform the system of the Vehicle at the Site and at which Fuelling Bay. If our LCD on the Pump does not automatically display the Vehicle details because the Fuelling Bay cannot be precisely identified, then there are three options.

- Use the Keyfob Tag on the Pump

- Enter the registration numerics in the Keypad and the system will offer the matching vehicles for section.

- Menu – Option: Searching for AVR Vehicles (Auto Vehicle Recognition)

- The RFID Tag number is then used to find the VIN number of the vehicle and this enables communication to a wifi device on the vehicles and with an established communication, the presence of the vehicle can be confirmed and the information about the position of the Fuelling Position of the Nozzle can be retrieved.

Via the CC1310 – Question: Does the uC have a unique ID like the MC has ?

It would be best to address the vehicle via the Unique ID and get the data from the Web regarding the registration, though it would be ideal to store such data on the vehicle device and be able write the last transaction.

- NB: Once the RFID reader is used and the FMS will send command to Shut down the RFID reader to conserve battery power. There is not further need for the Reader to be active.

- Once the Tag is read by the Nozzle, the nozzle must be put into a rest position in the Tank area with no movement for 3 seconds. This becomes the Locked Position of the Nozzle which is sent to the FMS. Once the FMS acknowledges this comm, the Nozzle will then only send a very abbreviated message that indicated that Nozzle is still in the LOCKED position.

- The Nozzle MCU will allow for minimal process but a configured percent tolerance is allowed. The LOCKED message is transmitted every 3 seconds to the FMS (fuel Management System ). Should the tolerance be violated, the transmission speed is

every seconds immediately with the parameter that has been violated. - Using the MEMS devices (Gyro, Compass and the accelerometer), the Nozzle must be able to track its special movement and know when it is back in its LOCKED position.

- If the Nozzle is not used during a fuelling process as the vehicle is not fitted with the technology, the FMS will send a SLEEP command that will enable the device to conserve power until the next transaction.

- Each Nozzle will have a unique ID#.

- The Nozzle will know the orientation of its REST position on the Pump when it is inactive (and no Movement) and this will put it into a SLEEP mode. The Sleep command can also be sent from the FMS.

- The Nozzle will transmit a byte in the message that will indicate its battery heath.

Battery Life

The device is expected to be active 3-5hours a day and the battery should last 2 to 5 years depending on use.